One-Touch Clamps are mechanical quick clamps developed for machining fixtures.

Quick and easy clamping by turning the handle slashes workpiece setup time and spiral cam mechanism provides high clamping force.

These unique tool-less clamps help to reduce time wasted on part setup and changeover while increasing overall productivity.

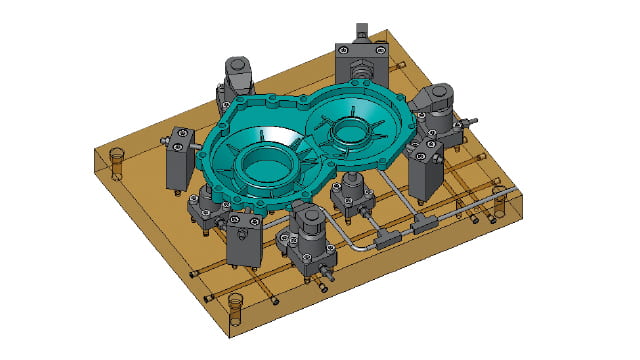

One-Touch Clamps are available in a wide variety of sizes, clamping forces, and clamping directions. A wide range of applications is covered, from multiple clamping of small workpieces such as aluminum to heavy-duty cutting of large workpieces such as iron castings.

Product Video

Feature

Quick & Easy Clamping with No Tool!

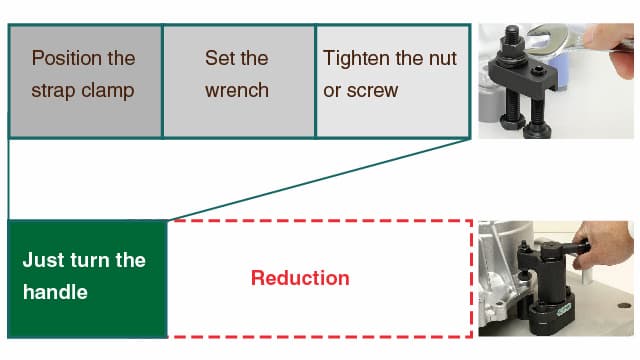

Tool-less quick clamping reduces workpiece setup times!

Just turning the handle completes clamping!

Quick clamping without tools leads to 1/3 workpiece setup time compared to old style mechanical clamps.

No need to prepare tools or turn screws!

Reliable for Machining Operations

One-Touch Clamps are designed as rigid clamps with high clamping force provided by the spiral cam clamping mechanism, ideal for machining fixtures.

Extensive Range of Clamping Options

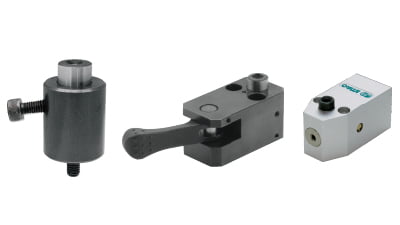

One-touch Clamps offer a wide variety of sizes, clamping forces, and clamping directions, including Push Down, Side Push, and Pull Down.

This extensive range makes them suitable for any application, from precision work with aluminum components to heavy-duty cutting of iron castings.

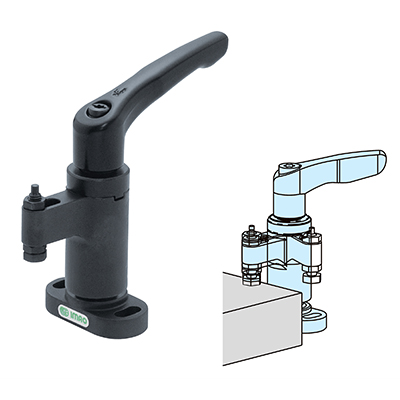

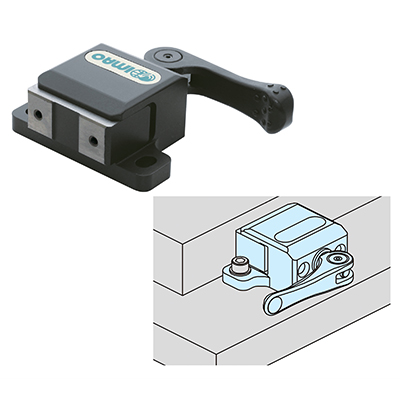

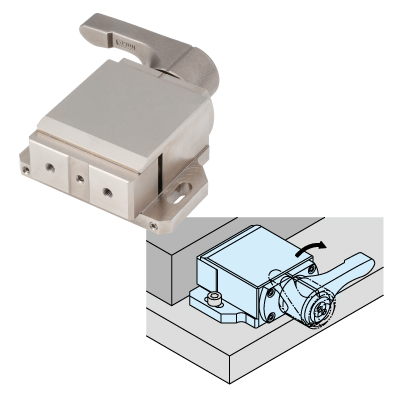

Push Down

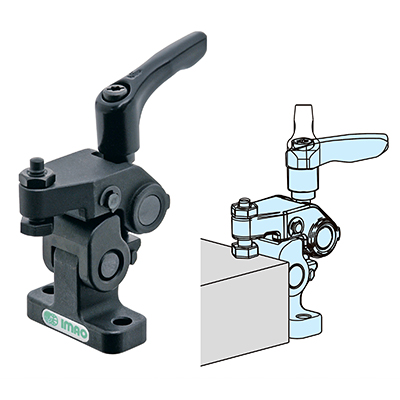

Side Push

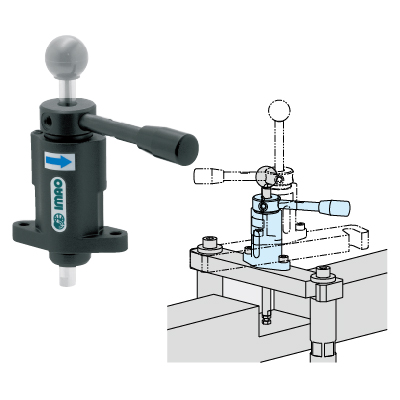

Pull Down

Additional Feature

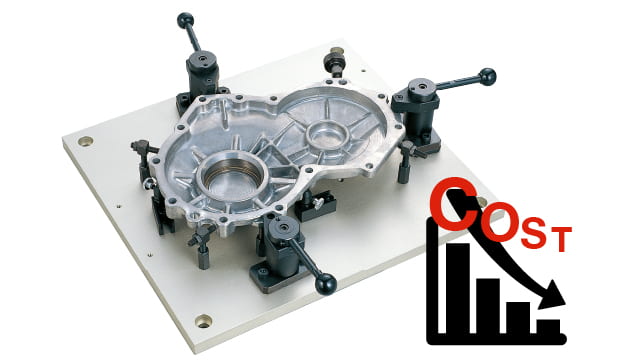

Simple Design Reduces Cost

Mechanically designed one-touch clamps simplify fixture design. This leads to cost-effective workholding.

Fixtures with hydraulic/pneumatic clamps not only have high unit costs but also require complex design and maintenance.

Fixture with One-Touch Clamps requires

- No piping

- No maintenance

Leads to a reduction in overall cost of fixture buildup

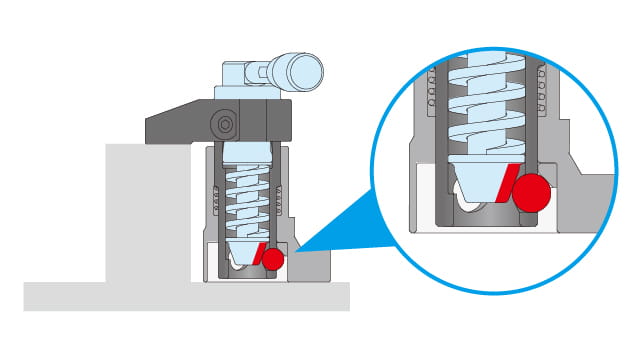

NEW Stable Lock Series for Constant Clamping Force

In a combination of mechanical positive clamping with a ball and tapered surface with spring force, these Stable Lock Series clamps provide constant and uniform clamping force.

The clamping force is constant no matter who works on the fixture, and the completion of a clamp is indicated by a click that ensures a reliable operation.

Spring-loaded constant clamping, positive locking with balls and tapered surfaces

Application

IMAO's mechanical quick clamps provide a workholding solution for machining, assembly and checking fixtures.

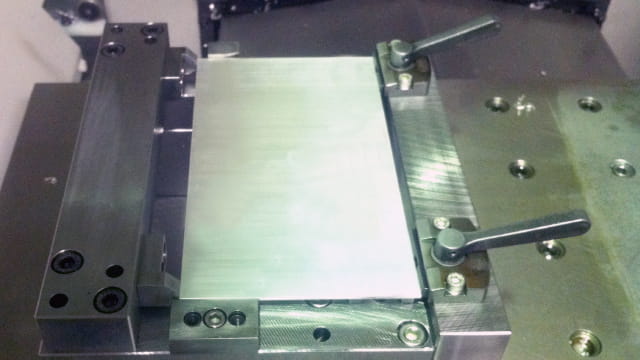

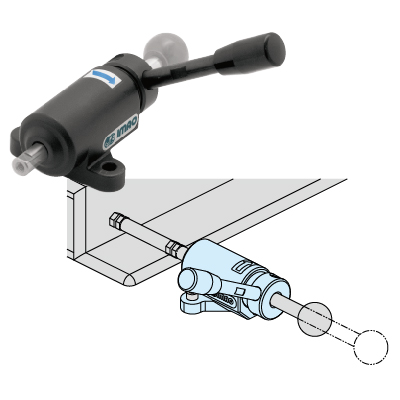

QLPDH Pull Clamp is utilized for interference-free hole drilling and milling on a horizontal machining center.

QLSCL-R Side Clamps featuring low profile design are utilized for hole and pocket machining on a vertical machining center.

Fixtures with one-touch swing clamps simplify operation for product inspection

Lineup

Push Down

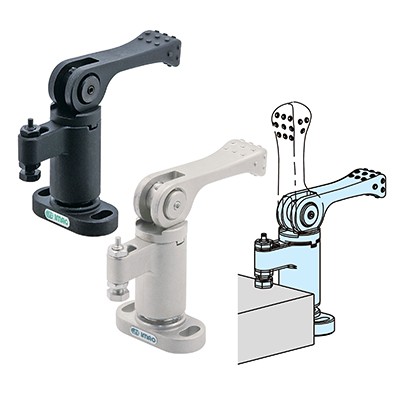

QLSWC

SWING CLAMPS

- Manual swing clamps

- Clamp arm swings along with handle operation

QLSWC

SWING CLAMPS with Cam Handle

- Swing clamps with vertical handle operation

QLSWC

SWING CLAMPS with Adjustable Handle

- Higher clamping force for heavy duty machining

- Longer clamping stroke for various workpiece dimensions

QLSW

SWING CLAMPS

- Replaceable Clamp Arm

- Adjustable Clamping Force

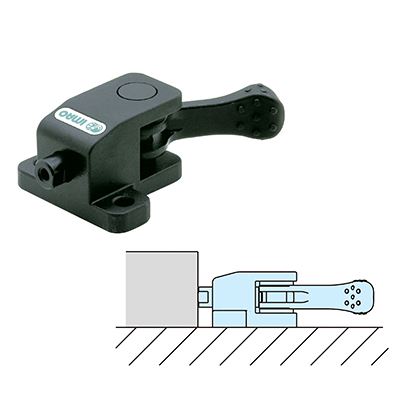

QLRE

RETRACTABLE CLAMPS with Cam Handle

- Retractable clamp arm

QLRE

RETRACTABLE CLAMPS with Adjustable Handle

- Higher clamping force for heavy duty machining

- Longer clamping stroke for various workpiece dimensions

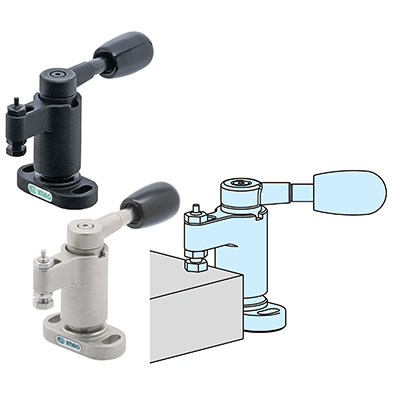

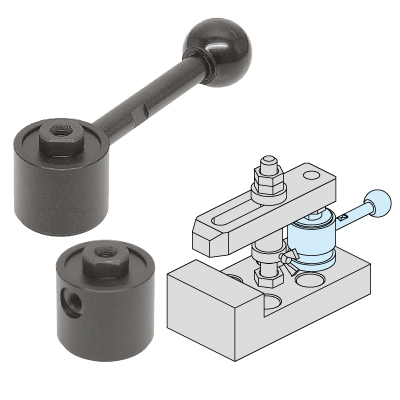

QLRCF

THRUST CLAMPS (Vertical)

- Long clamping bar travel to clamp recessed part

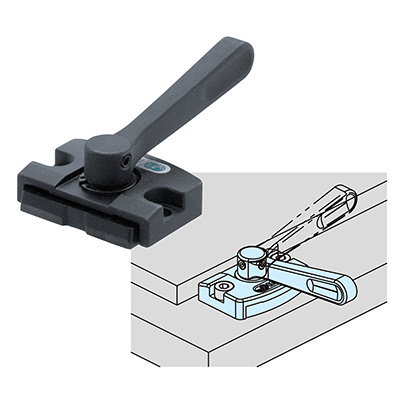

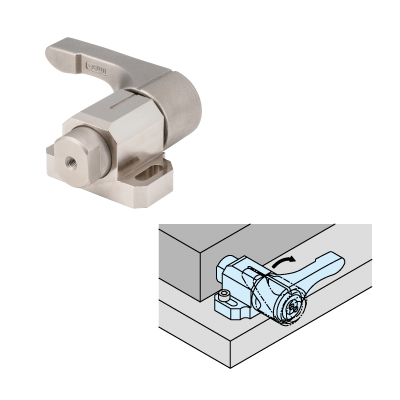

Side Push

QLRC

THRUST CLAMPS

- Long clamping bar travel to clamp recessed part

QLSCH

CAM EDGE CLAMPS

- Strong clamping for top surface machining

QLSCL-R

LOW-PROFILE CAM EDGE CLAMPS

- Low profile design is perfect for thin workpieces

CP135-L

SPIRAL CAM CLAMPS

- Compact cam clamps for limited space

QLSC

CAM EDGE CLAMPS

- Cam edge clamps to push down the workpiece

QLCP

CAM PUSH CLAMPS

- Horizontal clamps with cam handle

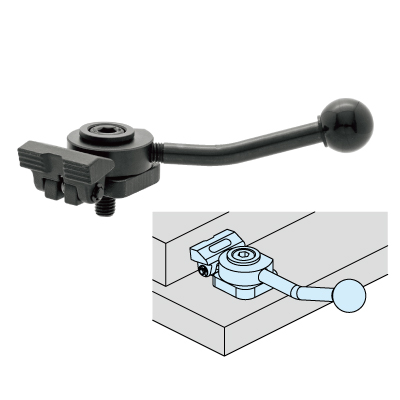

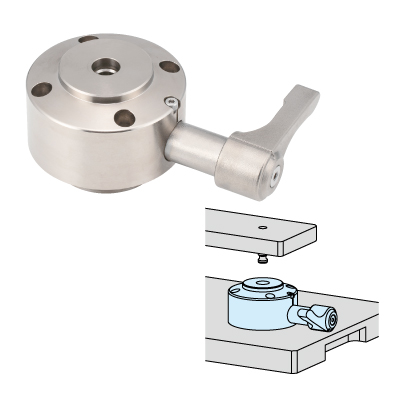

Pull Down

QLPD

PULL CLAMPS

- Pull down clamping

- Clamping pin or clamping screw are available

QLPDH

PULL CLAMPS (Heavy)

- Heavy duty pull clamps with higher clamping force

- Clamping pin or clamping screw are available

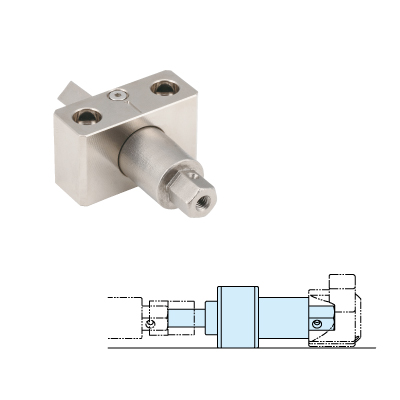

Push Up

QLPU

PUSH CLAMPS

- The piston pushes up the workpiece

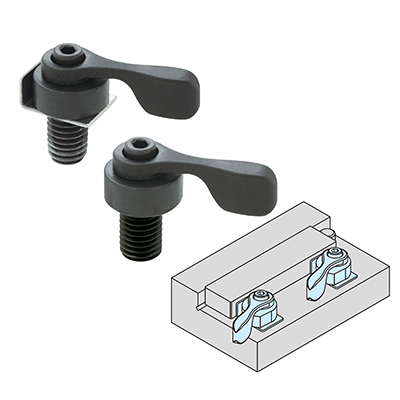

Handles

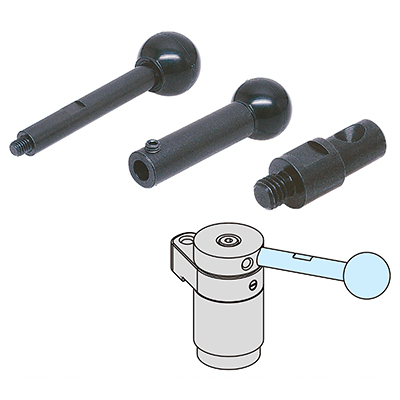

QLSL

STANDARD HANDLES

- Fixed or removable type

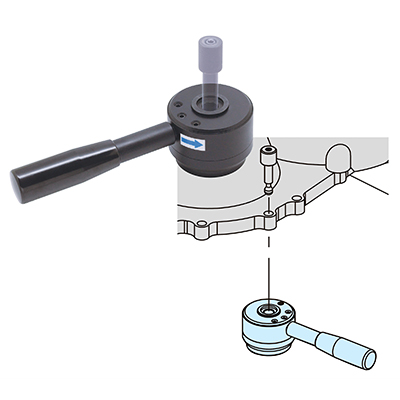

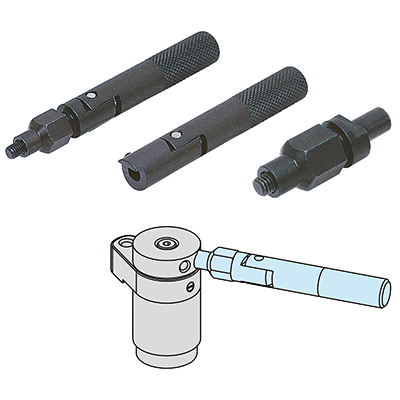

QLTL

ADJUSTABLE-TORQUE HANDLES

- Control clamping force

Stablelock Series

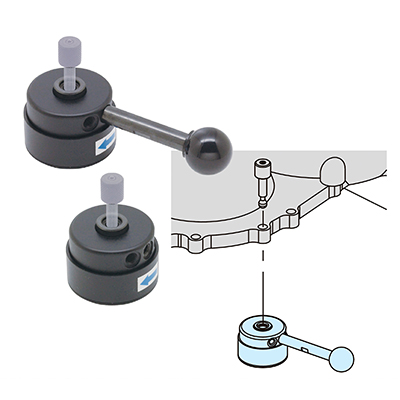

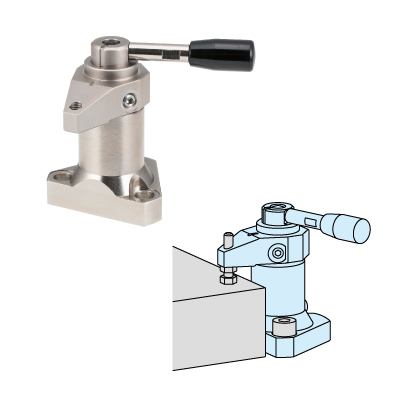

QLSWW

STABLELOCK SWING CLAMPS

- Constant clamping force at every operation

- Clamping completion is indicated with a click

- Clamp arm swings along with handle operation

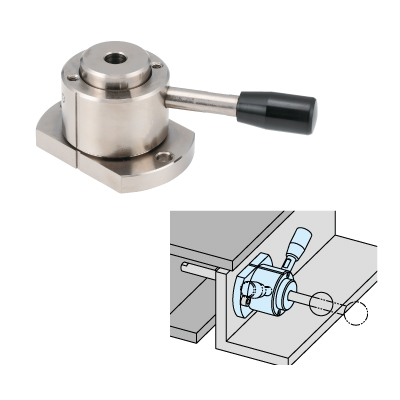

QLRCW

STABLELOCK THRUST CLAMPS

- Constant clamping force at every operation

- Clamping completion is indicated with a click

- Free clamp bar travel to clamp various parts

- Also available as a pull clamp

QLSCW

STABLELOCK SIDE CLAMPS

- Constant clamping force at every operation

- Clamping completion is indicated with a click

- Strong clamping for top surface machining

QLPUW

STABLELOCK PUSH CLAMPS

- Constant clamping force at every operation

- Clamping completion is indicated with a click

- Space-saving side clamp for top surface machining

QLPDW

STABLELOCK PULL CLAMPS

- Constant clamping force at every operation

- Clamping completion is indicated with a click

- Use with clamping screws to pull down the workpiece

- Pull-down clamping allows unrestricted access to cutting tools

QLPDW-RC

EXTENSION UNITS

- For use with QLPDW Stablelock Pull Clamps

- Clamp operation can be extended to any position, even out of reach

You may also like

Spring Clamps

Mechanical tool-less clamps with constant clamping force

Learn More about Spring Clamps

Pneumatic Clamps

Pnematic clamps with compact body and high clamping force

Learn More about Pneumatic Clamps

Nutrunner Clamps

Mechanical automation clamps for robotized production

Learn More about Nutrunner Clamps

Work Supports

Mechanical / pneumatic work supports to prevent vibration and deformation

Learn More about Work Supports