Robotic Workpiece Clamping with Nutrunner Clamps!

Mechanical Clamps for Automation

Clamping automation by Imao's Nutrunner Clamps serves as alternatives to hydraulic clamps.

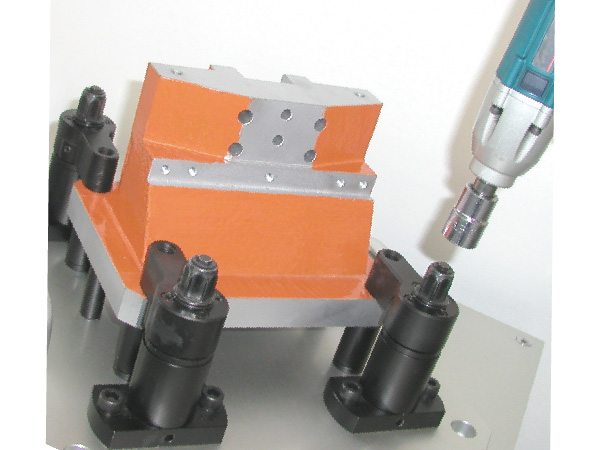

Tightening with nut runner installed on a robot actuates Nutrunner clamps to hold workpieces with high clamping force in machining and assembly line.

Mechanical design does not require hydraulic piping and simplifies fixture design and maintenance.

IMAO's robotic clamps achieve automated workpiece clamping with shorter fixture preparation time and lower fixturing cost than hydraulic clamps.

Product Video

Feature

Tightening Hex Head with Nut Runner

Allows automated clamping and unclamping in robotized production lines

High Clamping Force

10 kN clamping force for heavy duty applications

Ideal for machining and assembly lines

Mechanical Clamping with No Hydraulic Piping

Achieves easy fixture design & maintenance, low fixturing cost and pallet transfer

Additional Feature

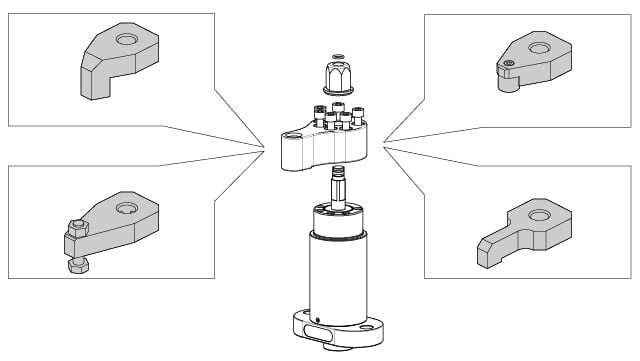

Custom Clamp Arm is Applicable

To meet the requirements in customers' applications

Sealed to Prevent Coolant, Dust and Chips

Long life time with minimum maintenance

Case Study

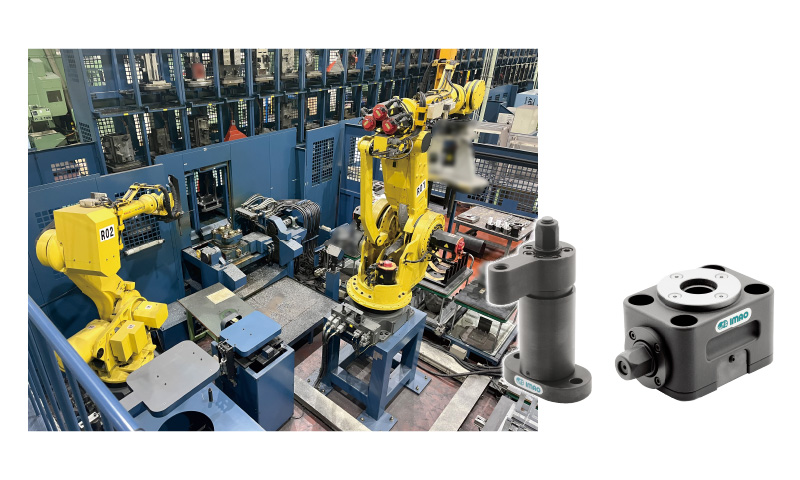

CASE 1 Robotic workpiece clamping boosted production volume tenfold!

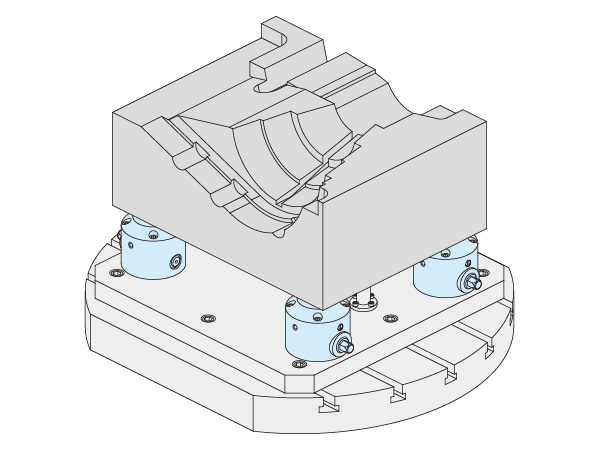

Matsuura Machinery Corporation is a machine tool manufacturer that offers innovative technology worldwide. They use IMAO's Nutrunner Pull Clamps and Swing Clamps in their fixtures for pallets and spindle housings of 5-axis machining centers.

Matsuura was tasked with increasing pallet production to accommodate the use of pallets from the existing machine to the new 5-axis machining center. They considered using the same manufacturing facility for nighttime machining but decided against it because workpiece setup requires manpower even during the night. They finally decided to transfer pallet machining to the flexible manufacturing system (FMS) line with robots, which had been machining other workpieces.

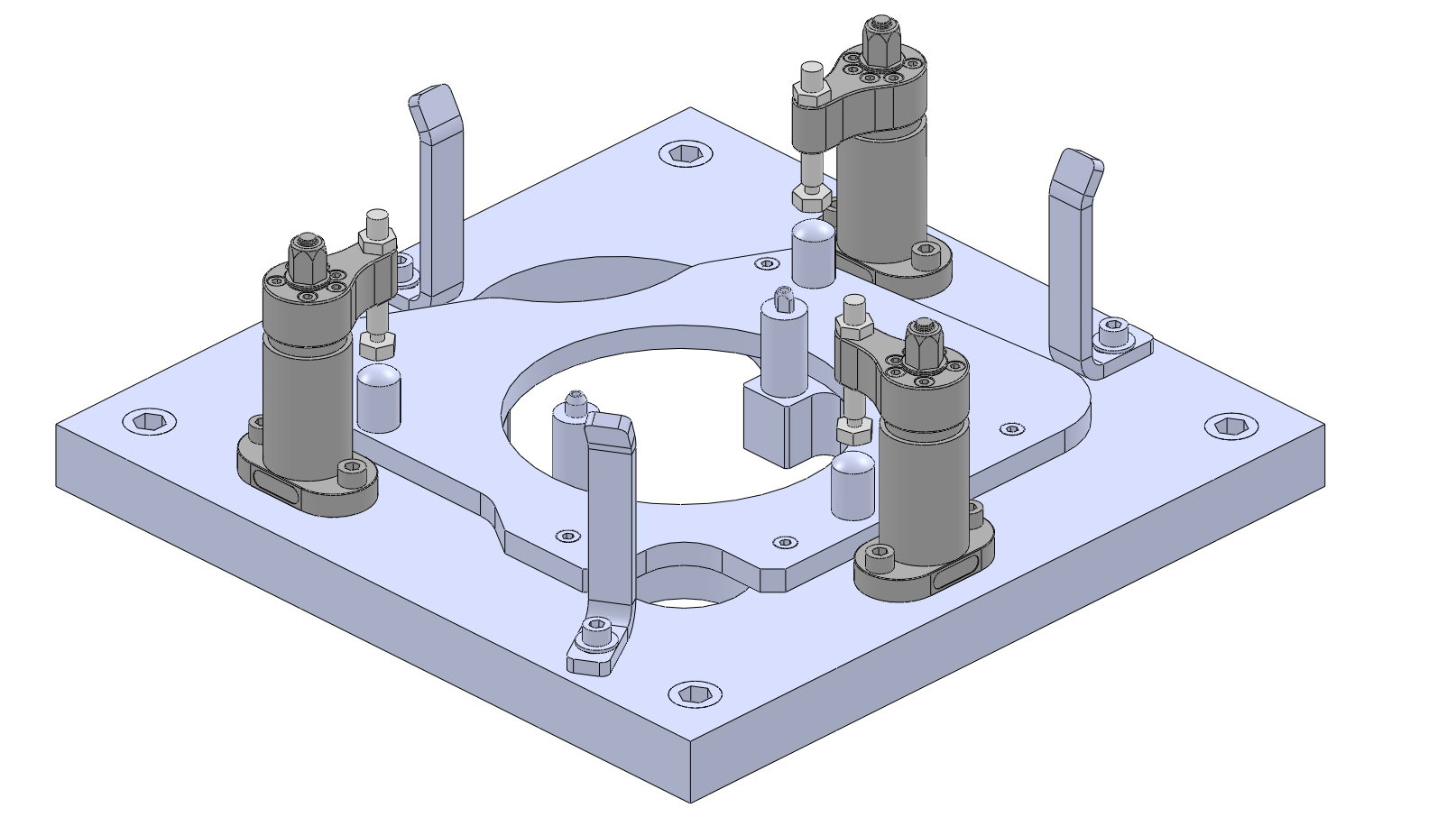

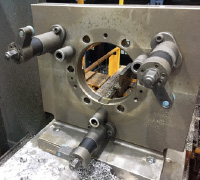

To manufacture the pallet, the bottom surface is machined first to make 4 tapped holes beforehand using another machining center. The operator installs clamping screws in the tapped holes and feeds the workpiece into the setup station, then the robot conveys it to the fixture. Another robot tightens Nutrunner Pull Clamps on the fixture for top and side surface machining. This enabled the robots alone to machine at night and significantly increased pallet production from one to ten per day.

Matsuura's engineering team then decided to relocate the production of multiple spindle housings to the same FMS line for greater efficiency. In the first operation, the robot transfers the part to the 1st fixture and tightens Nutrunner Swing Clamps to make tapped holes on the bottom surface. In the second operation, the spindle housing is manually secured on the 2nd fixture fitted with clamping screws and fed into the setup station. The 2nd fixture is conveyed by the robot to the machine pallet, and it is fixed on the pallet by Nutrunner Pull Clamps to machine the top and side surfaces.

Not only has Matsuura achieved a significant increase in production through robotic fixturing, but they have also enabled efficient machining of a wide variety of workpieces on the same line by using Nutrunner Clamps as a universal fixture. Operators are now able to perform more value-added tasks by having robots perform simple workpiece and fixture changes. They also appreciate that the mechanical design of Imao's nutrunner clamps simplifies fixture design and maintenance compared to hydraulic fixtures, and is also cost-effective.

Lineup

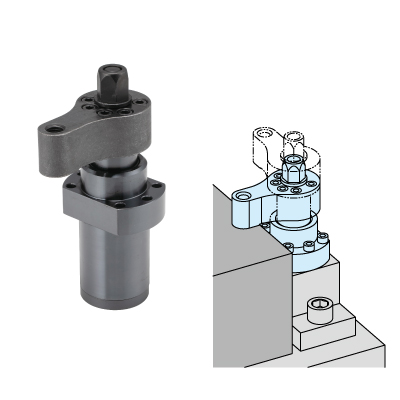

PTSW3 NEW

NUTRUNNER SWING CLAMPS

- The clamp arm swings positively along the inner spiral groove

- Provide rigid clamping by embedding to the plate

- Can be used with a custom clamp arm

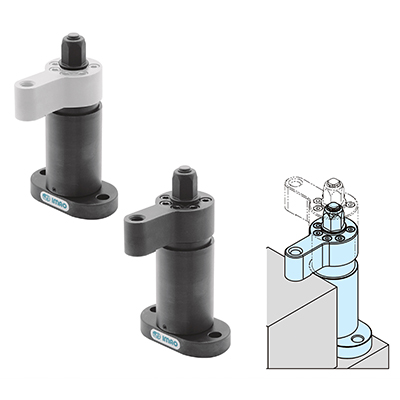

PTSW2

NUTRUNNER SWING CLAMPS

- The clamp arm swings positively along the inner spiral groove

- Flanged design enables easy mounting on plates

- Can be used with a custom clamp arm

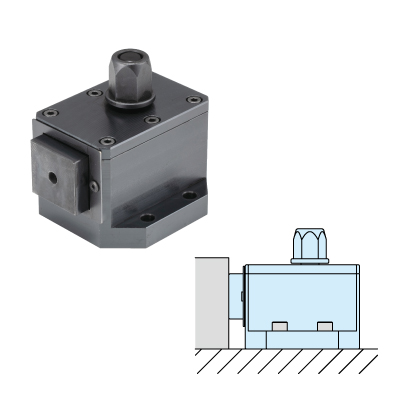

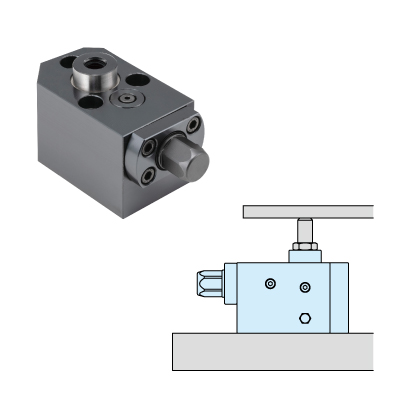

PTSC1 NEW

NUTRUNNER SIDE CLAMPS

- Hex. head on the top allows easy access of nut runners

- Jaw moves back and forth positively

- Grippers can be mounted on the jaw

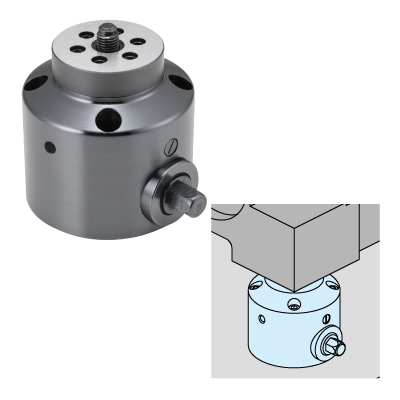

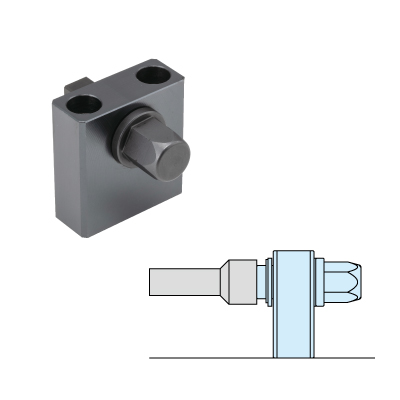

PTPD1 NEW

NUTRUNNER PULL CLAMPS

- Clamp workpiece directly by pulling in the tapped hole on the workpiece with the integrated clamping screw

- Clamping screw retracts in the body as the workpiece is loaded

- Applicable to M12/M16 tapped holes (other sizes available on request)

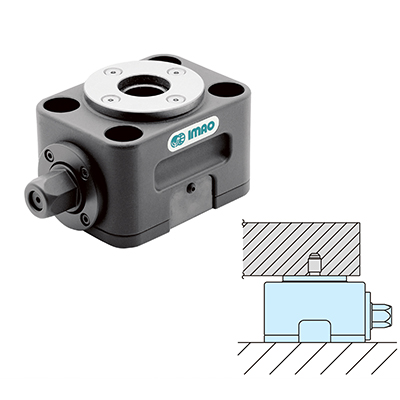

PTPD

NUTRUNNER PULL CLAMPS

- Clamp the workpiece by pulling down the clamping screws mounted on the workpiece

- Enable easy loading and unloading of workpieces by robots, as the clamping screws work as a guide

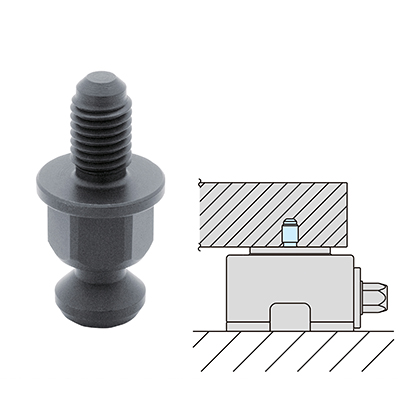

PTPD-M

CLAMPING SCREWS

PTNS1 NEW

NUTRUNNER WORK SUPPORTS

- Prevent workpiece vibration and deflection by operation of nut runner

- Support tips can be mounted on the piston

PTRC1 NEW

EXTENSION UNITS

- Suitable for operating Nutrunner Pull Clamps and Work Supports from a distance

You may also like

Pneumatic Clamps

Pnematic clamps with compact body and high clamping force

Learn More about Pneumatic Clamps

Pneumatic Flex Locators

Locating fasteners for machine changeover

Learn More about Pneumatic Flex Locators