Precise 5-axis Pull Clamps with Clear Tool Access

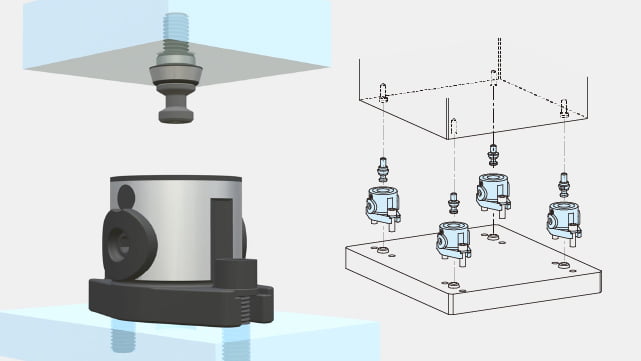

IMAO's Modular Pull Clamping System is a workholding system for 5-axis machining with precise locating repeatability of 0.005mm.

Pull-down clamping allows clear tool access and enables machining from five sides, leading to better machining accuracy with a single setup.

This simple mechanical system provides easy & precise positioning and clamping for 5-axis machining.

Product Video

Feature

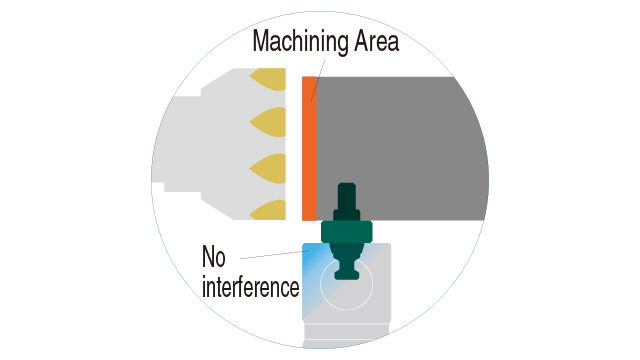

Pull-down Clamping

Workpiece is clamped by pulling in clamping screws, leading to:

- No tool interference

- Better machining accuracy by finishing in a single setup

- Suitability for 5-axis machining

Excellent Repeat Accuracy

0.005mm repeatability is achieved by taper-face dual contact of the clamping pin and the workpiece.

Quick & Easy Clamping

Positioning and clamping in one operation

Just turn three times with a hex wrench

Clamping screws are easy to install

Additional Feature

Riser Screws for Workpiece Raising

Allow easy tool access in machining operation close to clamping modules.

APPLICATION

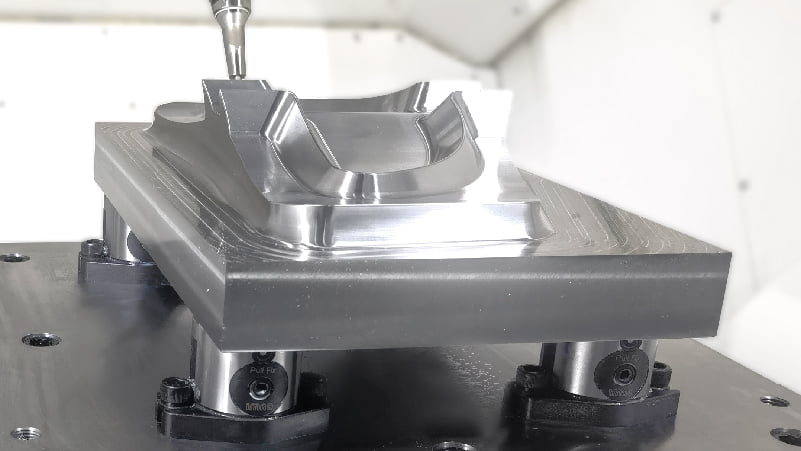

The pull-down clamps help prevent tool interference and ensure smooth machining of contoured surfaces during 5-axis operations.

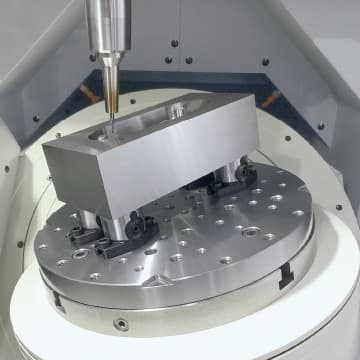

By using a double-unit setup on a large machining center, the mounting positions can be flexibly adjusted on the grid, making it easy to accommodate various workpiece sizes.

In horizontal lathe machining, the pull-down clamps enable stable and secure processing of heavy workpieces.

Case Study

CASE 1 Pull-down clamping system with high locating repeatability reduced setup time to one-fourth!

TOYO MACHINE MFG. manufactures parts for machine tools and industrial machinery. They machines various workpieces of 300 - 700mm square size in three processes with IMAO's Modular Pull Clamping System, which pulls down the clamping screws mounted on the bottom of the workpieces.

In the first process, the mounting holes are prepared for the clamping screws on the back of the workpiece using a vertical machining center. In the second process, the workpiece is placed horizontally on a horizontal machining center and clamped with Modular Pull Clamping System to machine the side surfaces. In the final step, the workpiece is clamped again with Modular Pull Clamping System on the tooling block, and the top surface is finished with a horizontal machining center.

In the past, they had to correct the position of the workpiece in the second and third processes to ensure that the reference surface was parallel perfectly to the machine pallet. It took a lot of time to measure the reference surface and make repeated fine adjustments to the workpiece position. In addition, the workpieces had to be machined from different positions, which made them difficult to clamp. Each time the machining area was changed, they had to stop the machine to move the conventional clamping straps to avoid tool interference. TOYO MACHINE considered this complex setup, which causes a decrease in the machine operating rate, to be a major problem.

This led them to adopt IMAO's Modular Pull Clamping System as the fixture of the second and third processes for rapid workpiece positioning and clamping, also 5-sided machining. The workpiece now can be quickly located by simply inserting the clamping screws into the clamping modules, eliminating the need for fine adjustments. Pull-down clamping allows the workpiece to be clamped without tool interference and also eliminates the need to change the position of the clamps.

The setup time was reduced from 105 minutes to 25 minutes for the second and third processes. The time and effort required to set up their fixtures were greatly reduced by eliminating the need to move the clamps.

TOYO MACHINE improved the setup and the machine operating rate using Modular Pull Clamping System.

Lineup

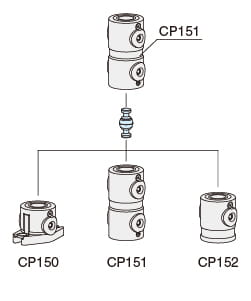

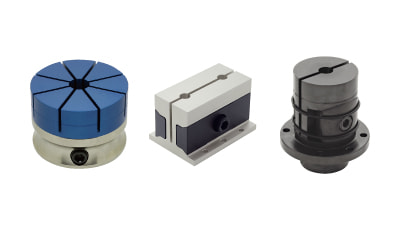

Clamping Modules

Locate and clamp a workpiece together with clamping screws.

Can be coupled with each type of Clamping Modules to increase height.

Available in flanged, double and single type.

CP150

CLAMPING MODULES (Flanged)

- Low-profile flanged design

- Easy mounting with screws

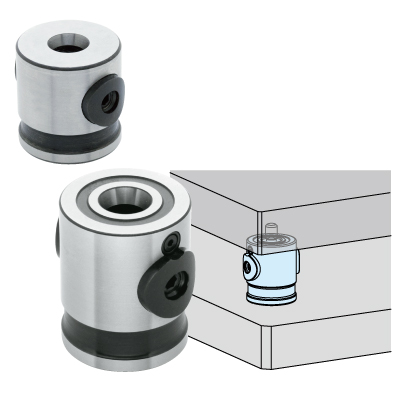

CP151

CLAMPING MODULES (Double)

- Flexible type with clamping mechanism on the top and bottom

CP152

CLAMPING MODULES (Single)

- Cylindrical design with small footprint

- For precise coupling

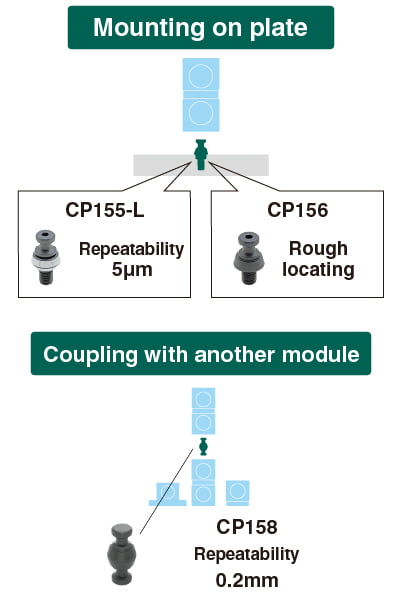

Clamping Screws

Attached to the bottom of the workpiece to pull it down.

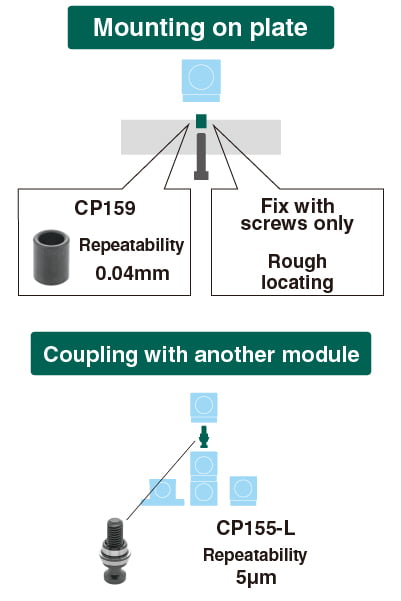

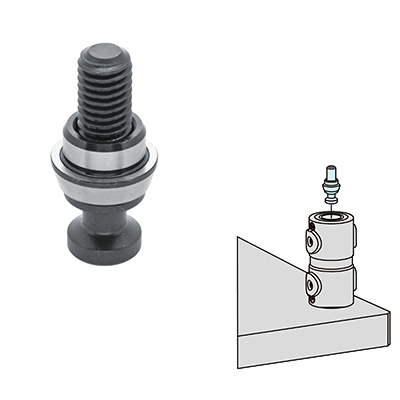

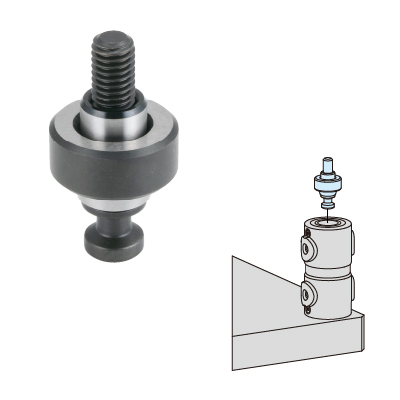

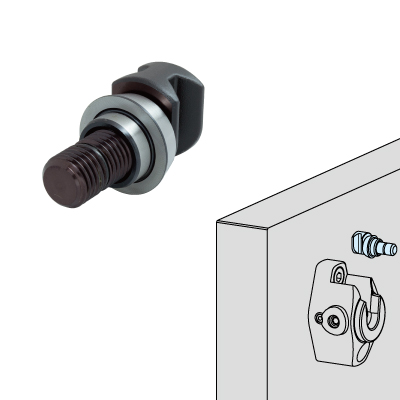

CP155-L

TAPERED CLAMPING SCREWS

- For precise locating

- All tapered surface is the reference

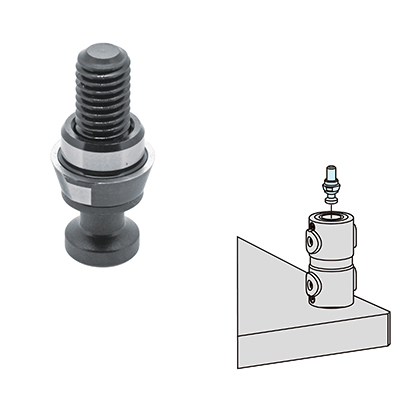

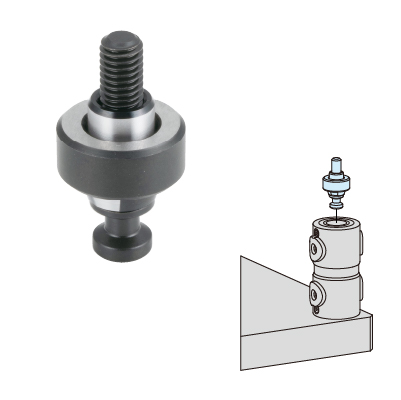

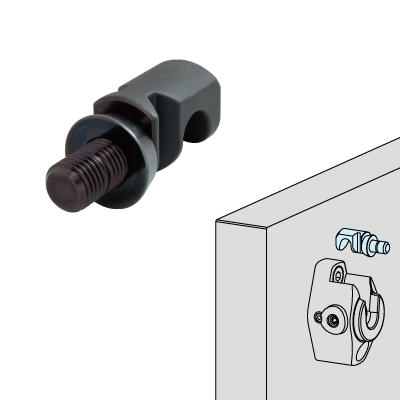

CP155-D

TAPERED CLAMPING SCREWS

- For precise locating

- Diagonal tapered surfaces are the references

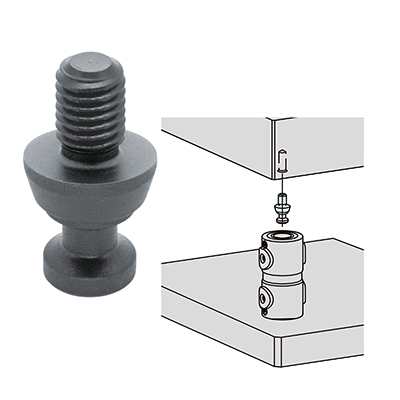

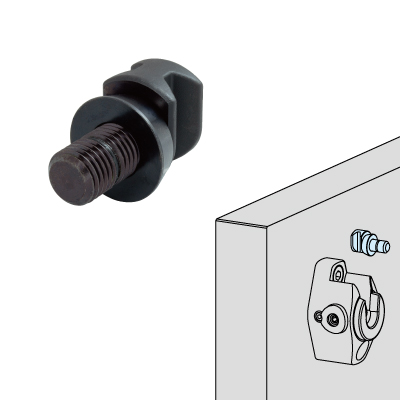

CP156

CLAMPING SCREWS

- For clamping

- No locating function

Riser Screws

For machining operation close to clamping modules

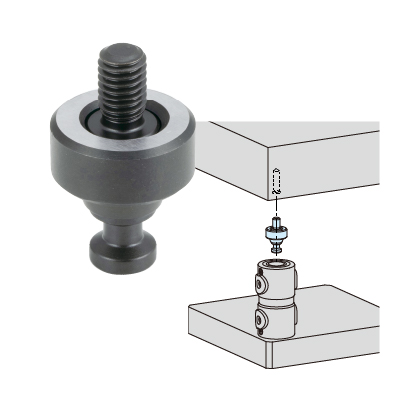

CP155-LS

TAPERED RISER SCREWS

- For precise locating

- All tapered surface is the reference

CP155-DS

TAPERED RISER SCREWS

- For precise locating

- Diagonal tapered surfaces are the references

CP156-S

RISER SCREWS

- For clamping

- No locating function

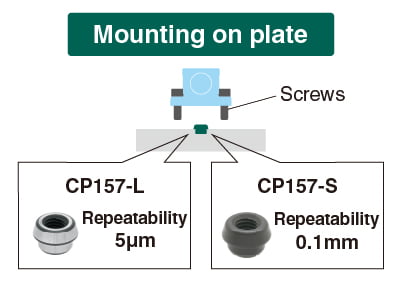

Accessories

CP157

TAPERED PINS

- For locating flanged modules

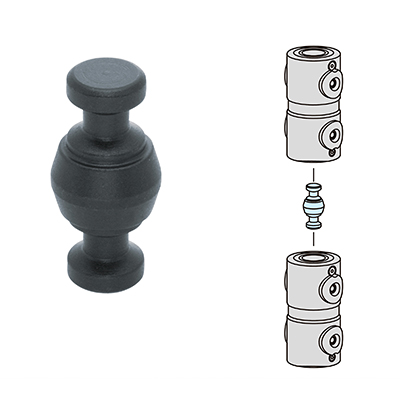

CP158

DOUBLE TAPERED CLAMPING PINS

- For coupling with double type modules

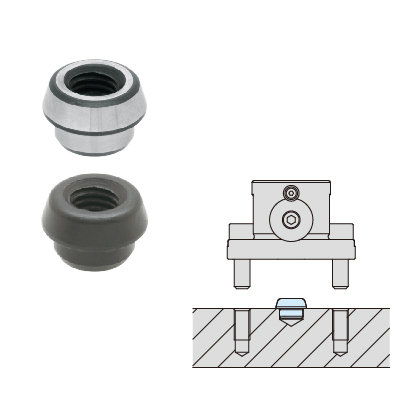

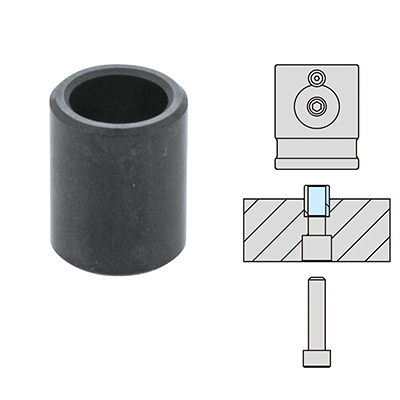

CP159

LOCATING BUSHINGS

- For locating single type modules

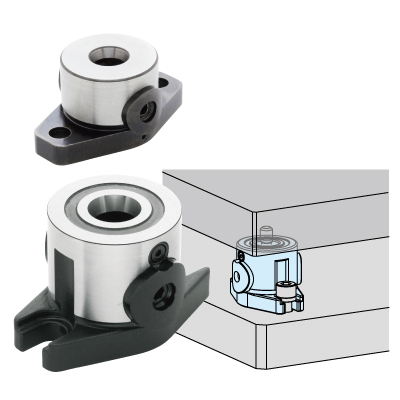

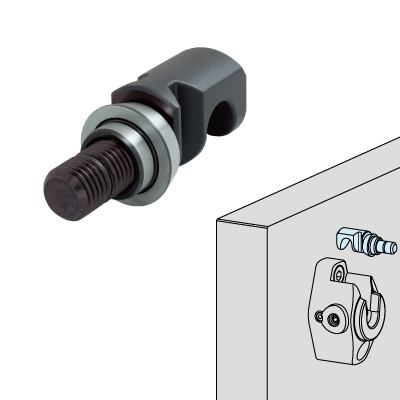

Hook Type

Hook-shaped clamping screw secures onto open module body to provide quick, safe clamping.

CP160

CLAMPING MODULES (Hook)

- For horizontal machining centers

CP165-LH

TAPERED CLAMPING SCREWS (Hook)

- For precise locating with hook

CP165-L

TAPERED CLAMPING SCREWS

- For precise locating without hook

CP166-H

CLAMPING SCREWS (Hook)

- For clamping with hook

CP166

CLAMPING SCREWS

- For clamping without hook

You may also like

Machinable Collet Clamps

Mechanical / pneumatic collets hold external and internal shapes

Learn More about Machinable Collet Clamps