Machinable Collet Clamps Hold Any Shape!

Custom-fit for small, thin, complex, and irregularly shaped workpieces — both OD and ID.

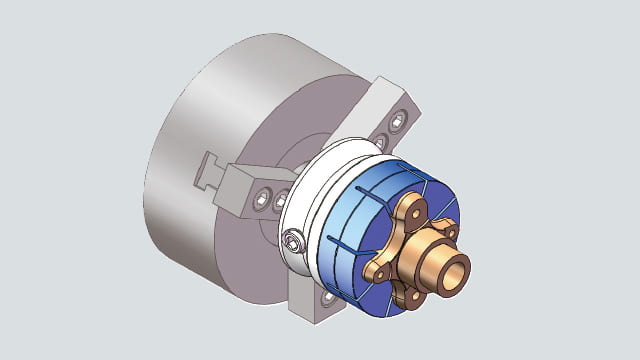

Machinable Collet Clamps hold both external and internal shapes of workpieces with a single tightening.

Ideal for machining small, thin, complex, and irregularly shaped parts on machining centers or turning lathes.

The collet is divided into up to 10 sections, distributing clamping force evenly along the outer or inner contour to prevent deformation.

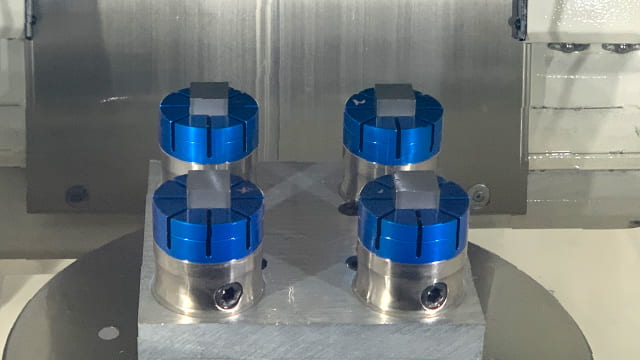

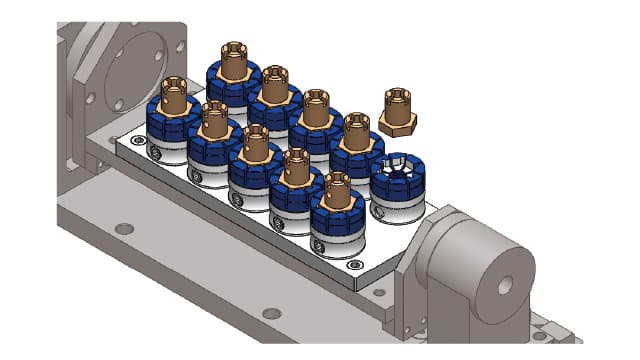

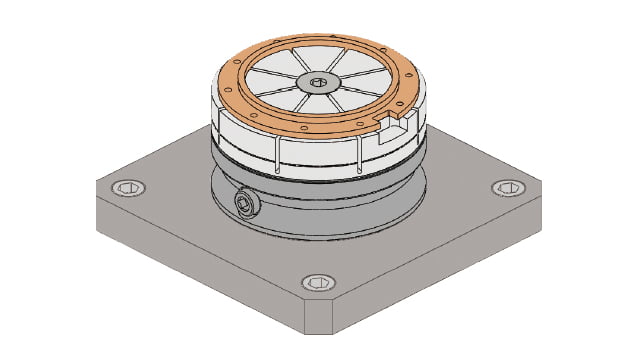

Its compact body allows for multiple clamps to be mounted on a single fixture plate.

This simple workholding solution helps reduce time and effort in fixture design.

Product Video

Feature

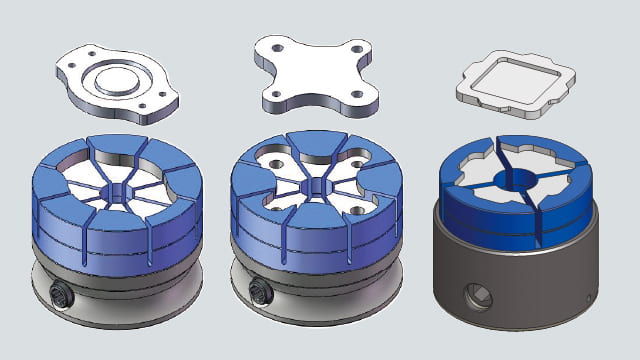

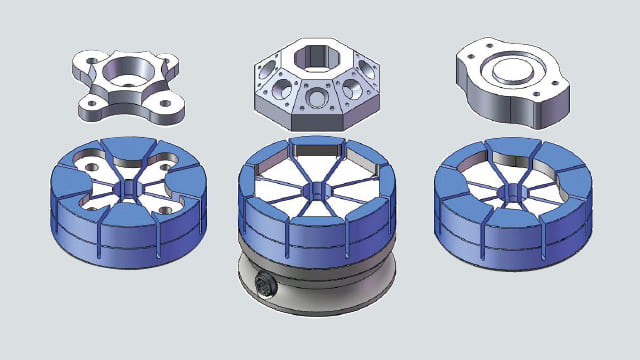

Machinable Jaw

Any shape can be clamped by machining the jaw to fit the contour of external or internal workpieces.

Divided Collet Jaw for Uniform, Secure Clamping

A multi-segment collet mechanism applies uniform force along the contour, ensuring secure and deformation-free clamping.

Quick and Simple Operation

Clamping is achieved with a single tightening or by supplying compressed air—no complex setup required.

Compact Design

Its compact body enables multiple clamps to be installed in tight spaces, maximizing fixture efficiency.

Additional Feature

Changeable Jaw for Flexible Workholding

Changing the jaw allows quick adaptation to different workpiece shapes, making dedicated fixturing faster and more cost-effective.

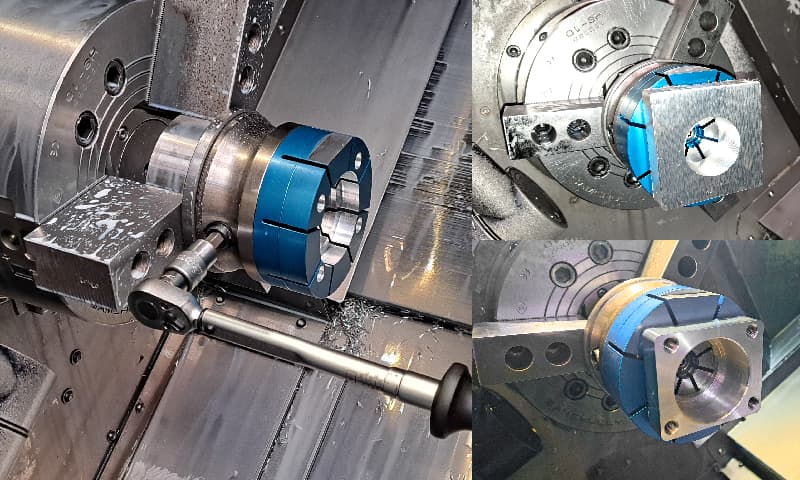

Versatile Clamping for Turning Applications

Complex or irregularly shaped parts that are difficult to hold with a standard chuck can be securely clamped using machinable jaws—ideal for turning operations.

Application Example

Clamping Low-Profile Workpieces

Thin parts can be securely held using internal clamping jaws that distribute force evenly through 8 jaw sections.

Proper torque control ensures optimal performance and prevents deformation of delicate parts.

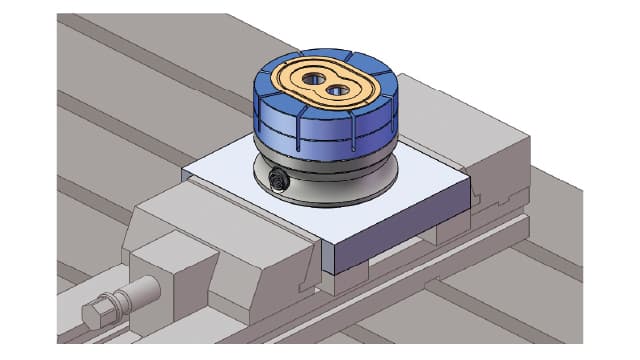

Temporary Fixturing on Vises

The clamp can be quickly mounted onto an existing vise using a fixture plate — ideal for short-run or trial jobs.

Case Study

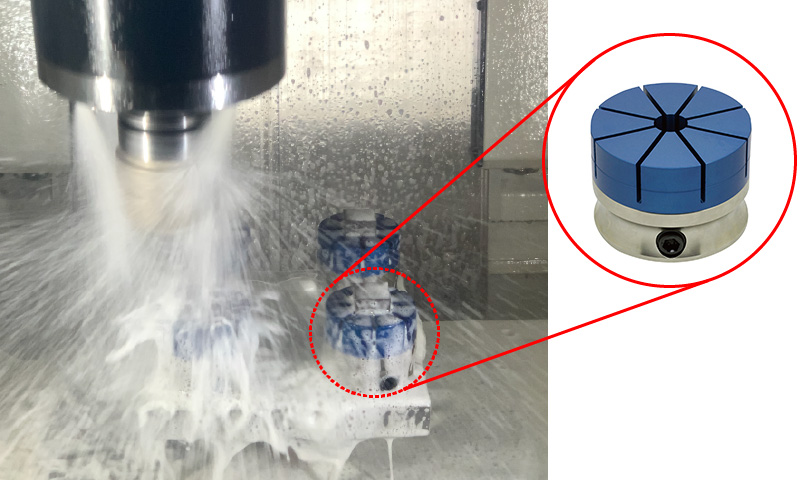

Multi-Part Clamping for 5-Axis Machining

KINKI KOGYO Inc., a manufacturer of hydraulic cylinder components and other precision parts, implemented IMAO's Machinable Collet Clamps to optimize their 5-axis machining operations.

Before

The company used several types of vises or dedicated fixtures to hold one part at a time, requiring multiple setups and high fixture costs.

This limited machine utilization, especially during unmanned night-time operation.

After

By adopting Form Holding Clamps, they were able to clamp four workpieces simultaneously on one fixture plate.

This significantly reduced setup time and cost, and increased machining efficiency—especially during overnight runs.

Results

- High clamping force with collet-style design ensures stability

- Compact body allows dense fixture layouts

- Replaceable jaws enable flexible clamping of OD and ID shapes

Deformation-Free Clamping for Thin-Walled Workpieces

MGG Třešť s.r.o., based in the Czech Republic, is a manufacturer specializing in aluminum casting, machining, and assembly.

The company originally used Form Holding Clamps to secure complex-shaped components in their production, and later discovered another practical way to use them—by customizing the clamps to fit thin-walled workpieces.

Before

Clamping thin-walled workpieces in a chuck did not prove effective, as they either deformed or slipped under the jaw pressure.

After

By machining the Form Holding Clamps to match the shape of the thin-walled workpieces, the clamping pressure was evenly distributed around the circumference, keeping them stable and securely held throughout machining.

Results

- Custom-machined jaws that fit the workpiece enabled stable and deformation-free machining of thin-walled components.

- Improved setup stability leads to higher productivity.

- Production is optimized in terms of cost and consistent quality.

Lineup

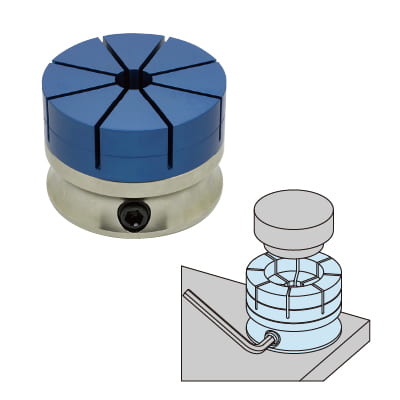

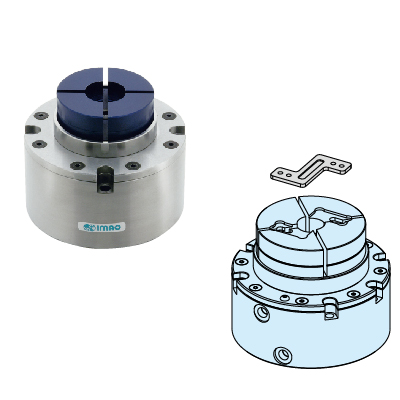

FORM HOLDING CLAMPS

- Secure clamping with 8 collet sections

- Changeable jaw

- Also available for ID clamping

- Can be mounted on turning lathes

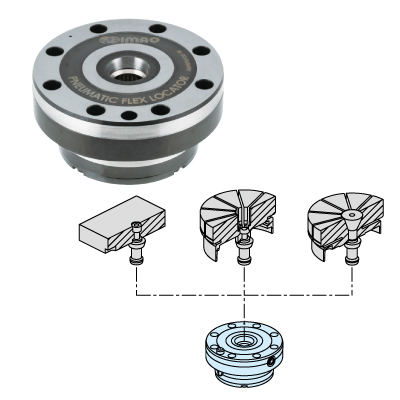

PNEUMATIC FORM HOLDING CLAMPS

- OD/ID clamping with machinable & interchangeable jaw

CONCENTRIC OD HOLDING CLAMPS

- Strong clamping force with compact body

- Completely through clamping for long parts

- For torque control

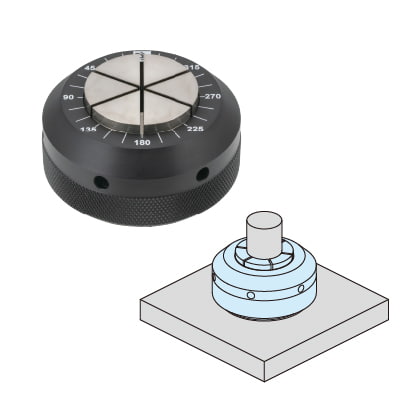

OD HOLDING CLAMPS

- Secure clamping with 4 collet sections

- Changeable jaw

- Can be mounted on turning lathes

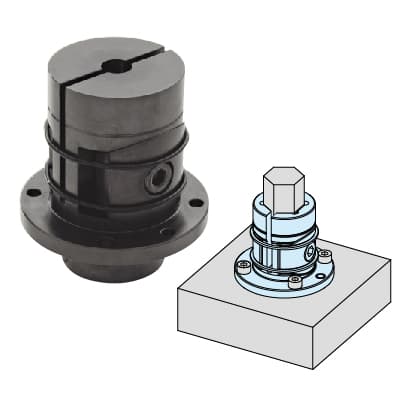

OD HOLDING CLAMPS (Wedge Style/Round)

- For clamping small parts with compact body

- Can be mounted on turning lathes

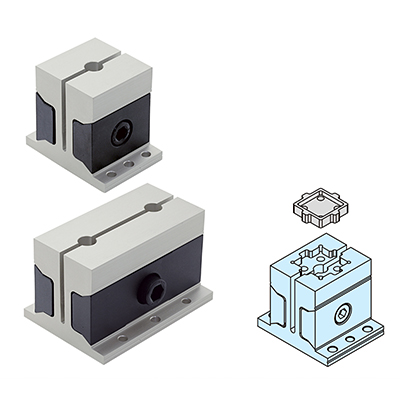

OD HOLDING CLAMPS (Wedge Style/Square)

- For dual-clamping two small parts / single-clamping one long part

PNEUMATIC OD HOLDING CLAMPS

- Pneumatic clamping for automated fixtures

- Changeable jaw

You may also like

Modular Pull Clamping System

Precise 5-axis pull clamps with clear tool access

Learn More about Modular Pull Clamping System