Quick Change Plate Completes Fixture Setup in 30 Seconds

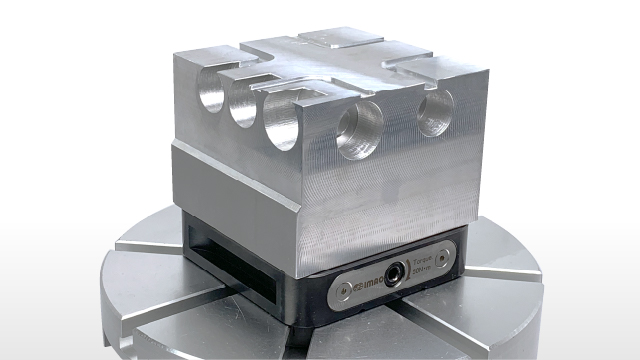

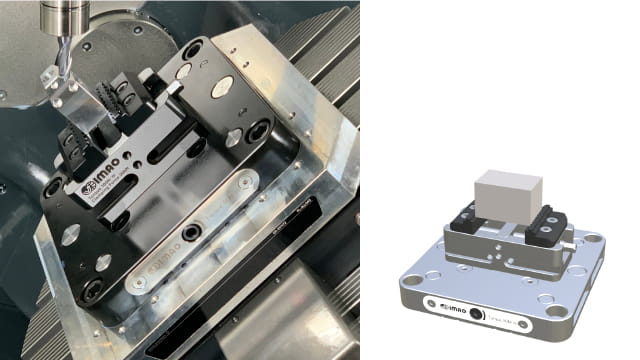

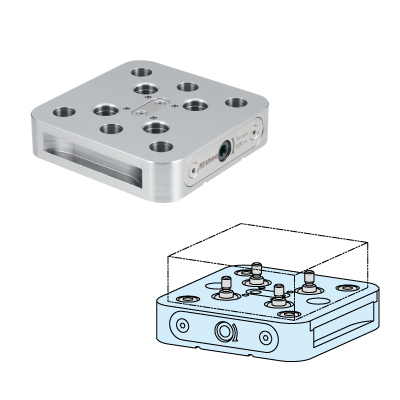

Flex Zero Base is a quick change plate with 0.005 mm repeatability and 15 kN clamping force.

4-point clamping by only one actuation screw drastically shortens machine down time during fixture change operations.

Compact body is perfect for quick change on small 5-axis machining centers and vertical machining centers.

Product Video

Feature

Quick Clamping

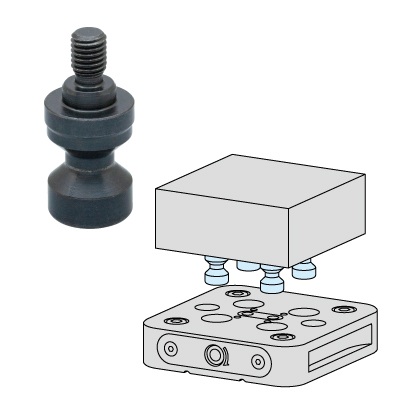

4-point clamping by only one actuation screw

0.005 mm Repeatability

2 jaws locate and clamp the pull studs with high accuracy.

Precise and quick fixture change

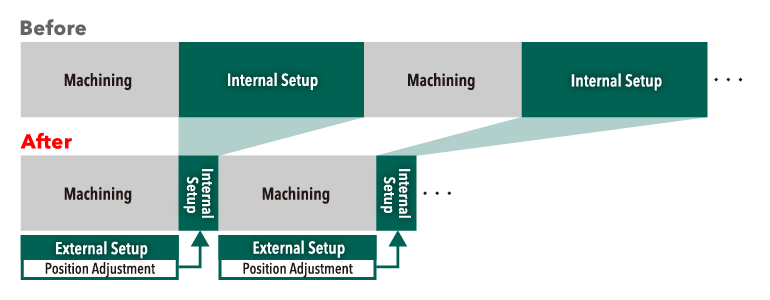

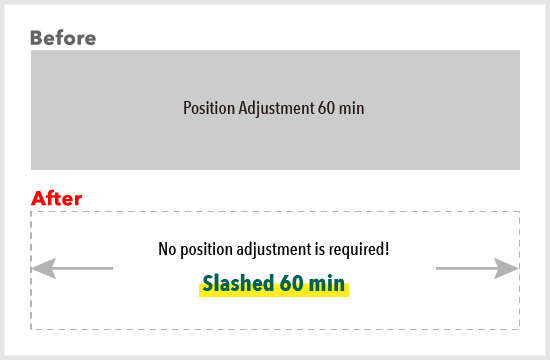

No Position Adjustment / Shorter Machine Down Time

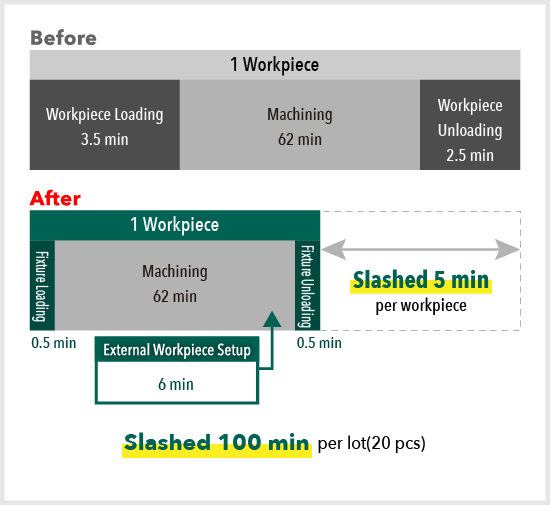

Benefit of External Workpiece Setup

External workpiece setup and quick fixture change reduce machine downtime and increase machine operating rate.

Additional Feature

15 kN Clamping Force

Strong clamping with 15 kN force allows heavy duty machining.

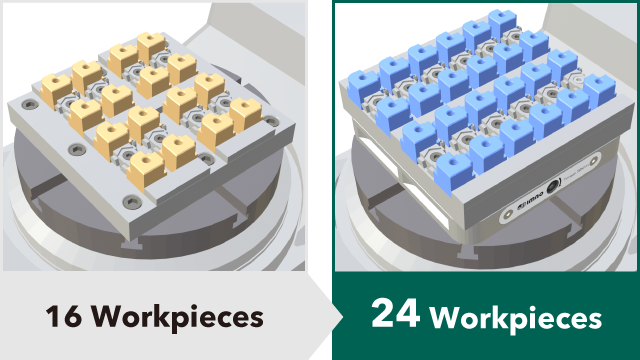

Multiple Workpieces Holding

Flex Zero Base maximizes fixture spaces for clamping multiple workpieces.

Compact Design

Two sizes of 150 / 240 mm are available depending on the size of machine table.

The low height of 35 mm maximizes the machining area.

Application

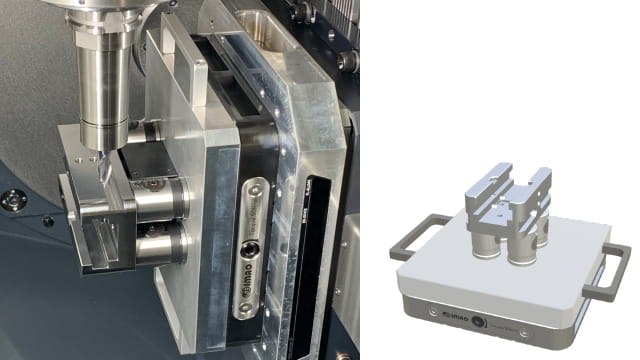

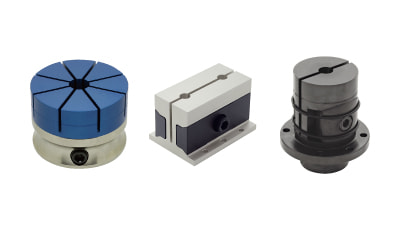

Fixture Plate

Centering Clamp

Case Study

Slashed 2.7 hours by Flex Zero Base!

Comparison of machining time for single production lot with and without Flex Zero Base

| Production lot | Machining time |

|---|---|

| 20 pcs | 62 min |

Quick fixture change slashed 60 min.

Flex Zero Base provides quick fixture change and eliminates position adjustment.

External setup slashed 100 min.

External workpiece changeover shortens setup time by 5 minutes!

Case Study

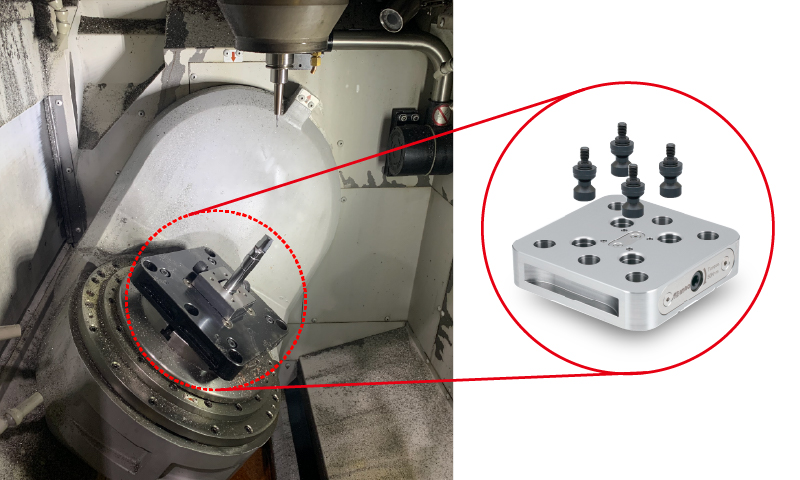

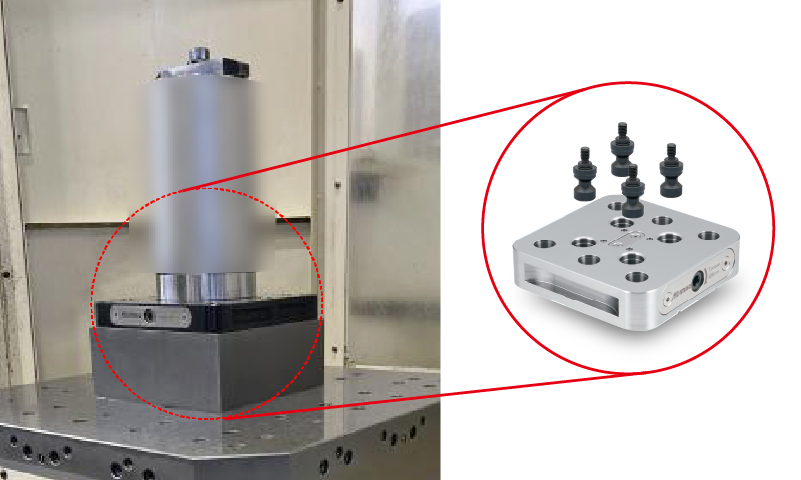

CASE 1 30 seconds fixture change on 5-axis machine

UOGISHI SEIKI INTERACTIVE CORPORATION manufactures die casting molds for major automobile manufacturers. They use IMAO Flex Zero Base to change fixtures on their 5-axis machining center. They produce mold parts made of tool steel in single part production with this 5-axis machining center.

Previously, operators had to stop machines for changing fixtures and mounting workpieces in the machine, once workpieces changed. It took 30 to 60 minutes to set up and this depressed machine operating rate. This was an issue for UOGISHI SEIKI.

Therefore, UOGISHI SEIKI introduced Flex Zero Base to mount fixtures onto the machine tables, after locating and clamping workpieces outside the machine. Since Flex Zero Base positions fixtures or vises with an accuracy of 0.005 mm and clamps 4 pull studs by only one actuation screw, fixture exchanges are now completed in 30 seconds. UOGISHI successfully improved their machine operating rate. In addition, they are satisfied with the high clamping force of 15 kN which allows heavy duty machining for hard materials.

CASE 2 Automation of centering optimized machine operating rate and labor force

Based on their philosophy of high precision and high efficiency, SHINKAWA uses a variety of selected equipment to machine single parts for automotive molds and machine components. SHINKAWA introduced IMAO's Flex Zero Base to reduce internal setup time in high-mix low-volume production on their new 5-axis machining center.

Previously, internal settings such as centering workpieces and fixtures were done manually. It took up to 20 minutes per set-up, even for a skilled operator, meaning that the machine had to stop during this time.

This led SHINKAWA to introduce Flex Zero Base on the machine pallets of their 5-axis machining center to change the fixture plates. Flex Zero Base positions the fixture plate with an accuracy of 5 µm, so that NC program correction can now be done automatically using only the 5-axis machining center's touch probe.

This enabled automation of the centering process, reducing the setup time from 20 minutes to about 5 minutes. The machine can now operate continuously for long periods of time without stopping, and the machine operating rate has dramatically improved. Since anyone can easily install the fixture plate by a single tightening operation with Flex Zero Base, skilled operators can now work on more difficult tasks, which is also a great achievement for labor saving.

Lineup

CP180

FLEX ZERO BASES

CP185

CLAMPING PINS

CP185-P

PROTECTING COVER

You may also like

Modular Pull Clamping System

Mechanical zero point clamping system for quick change fixturing

Learn More about Modular Pull Clamping System

Machinable Collet Clamps

Mechanical / pneumatic collets hold external and internal shapes

Learn More about Machinable Collet Clamps